Introduction with Problem

In industries like mining, construction, cement, and steel, equipment is exposed to constant friction, impact, and abrasive materials. This leads to fast wear and tear of machine components, causing frequent breakdowns and costly downtime.

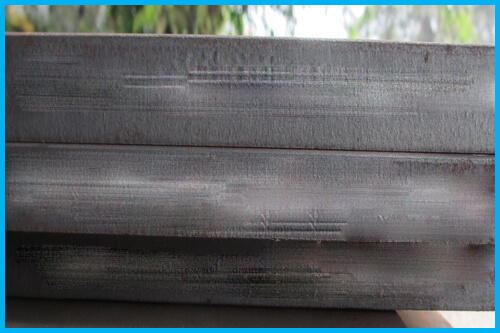

Product Introduction

Abrasion Resistance Plates are specially manufactured steel plates designed to resist excessive wear in harsh environments. They are used as protective liners to safeguard high-friction areas in machinery, ensuring better performance and longer service life.

Advantages Only

-

Exceptional resistance to wear, impact, and corrosion

-

Increases the operational life of machinery

-

Reduces maintenance and repair costs

-

Available in various grades like AR400, AR500, etc.

-

Can be cut, welded, and shaped for custom applications

-

Improves equipment productivity and efficiency

Real Life Uses

-

Mining: Used in dump truck beds, chutes, hoppers, and crushers

-

Cement Plants: Liners in raw mills, ducts, and separators

-

Steel Plants: Protection in slag zones and furnaces

-

Construction: Excavator buckets, dozer blades, and loader pans

-

Agriculture: Grain handling systems, feed mixers, and ploughs

How They Solve Problem & Outcome of the Product

The Problem: High-friction environments damage unprotected parts quickly.

The Solution: Abrasion Resistance Plates form a tough, protective layer that absorbs the wear, preserving the underlying equipment.

The Outcome: Significantly longer service life of machinery, reduced downtime, and greater cost-efficiency over time.

Call to Action

Looking for strong, reliable wear protection?

Get in touch with leading suppliers of Abrasion Resistance Plates for high-quality solutions tailored to your needs.

Contact us today for a quote or expert consultation.

Conclusion

When it comes to protecting your equipment from wear, Abrasion Resistance Plates offer the strength, durability, and performance you can count on—making them a smart investment for any heavy-duty operation.